A Better Surf Experience

Driven by Experience, Designed by Surf Engineers

Remora Surf™ is not about fashion, its about velocity.

We build systems that load fast and hold fast for zero distraction and maximum speed between loading and the lineup.

Global R&D - Portugal + Aus.

The Remora system was born from a collaboration between two distinct surf zones, backed by years of product experience.

Darryl (Sydney, Australia)

Product Design | BEng (Mech) UNSW

Based in the heart of the daily urban surf commute Focused on speed and efficiency, and the "10-second transition" to optimise the daily strike mission.

Daniel (Portugal)

Product Design, Manufacturing | M. Eng (Mech) U de Aveiro

Based on the rugged Atlantic coast. Focused on durability, material science, and ensuring the system withstands the harsh salt, wind, and extremes of the European winter, getting you strapped down and into a warm car faster after surfing the freezing Atlantic waters.

Together, we apply trusted engineering principles to the problems we as surfers care about.

Born in Sydney. Refined in Portugal. Scaled for the World.

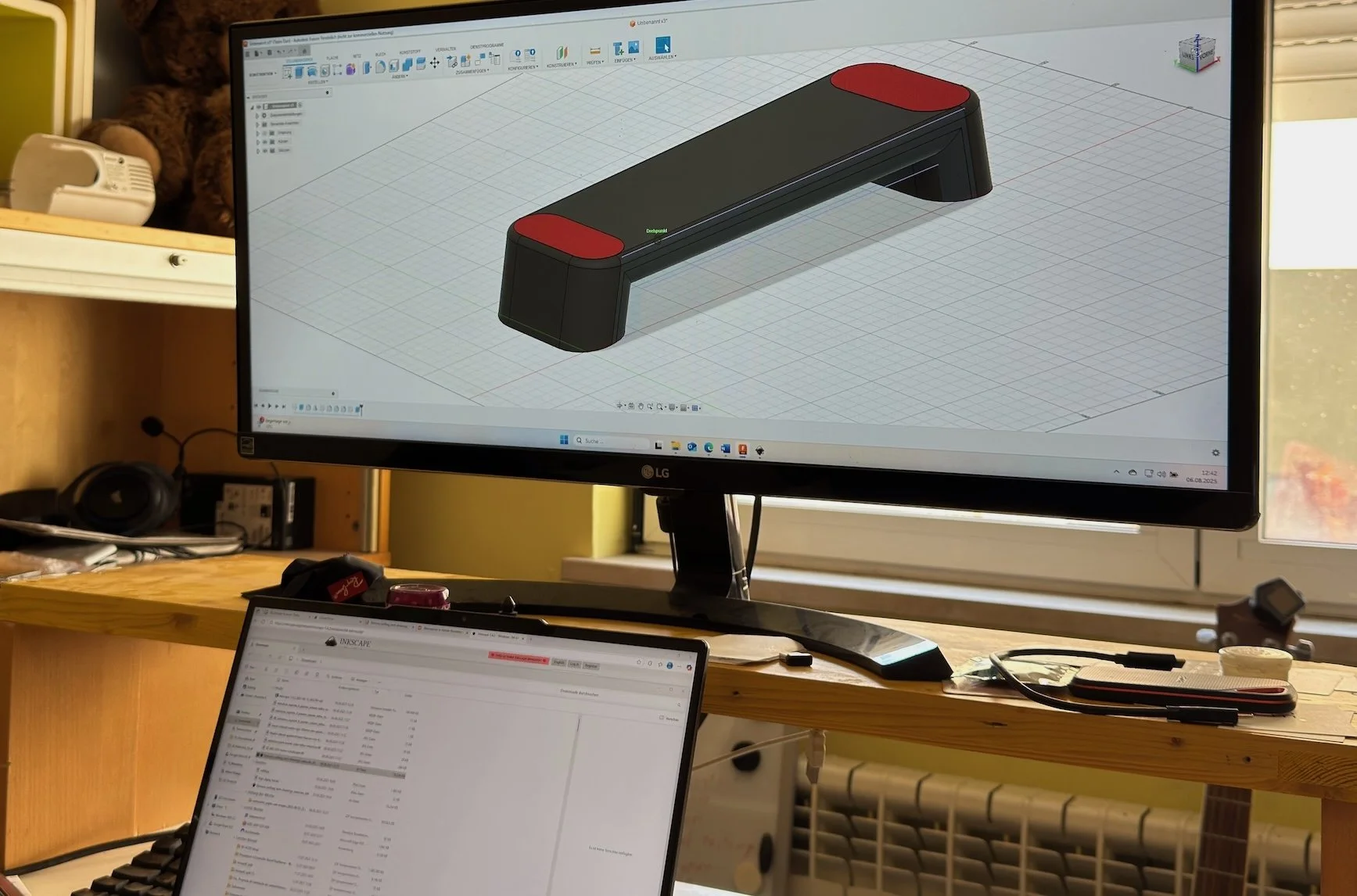

The Remora journey follows a rigorous development arc, moving from concept to global-ready scale.

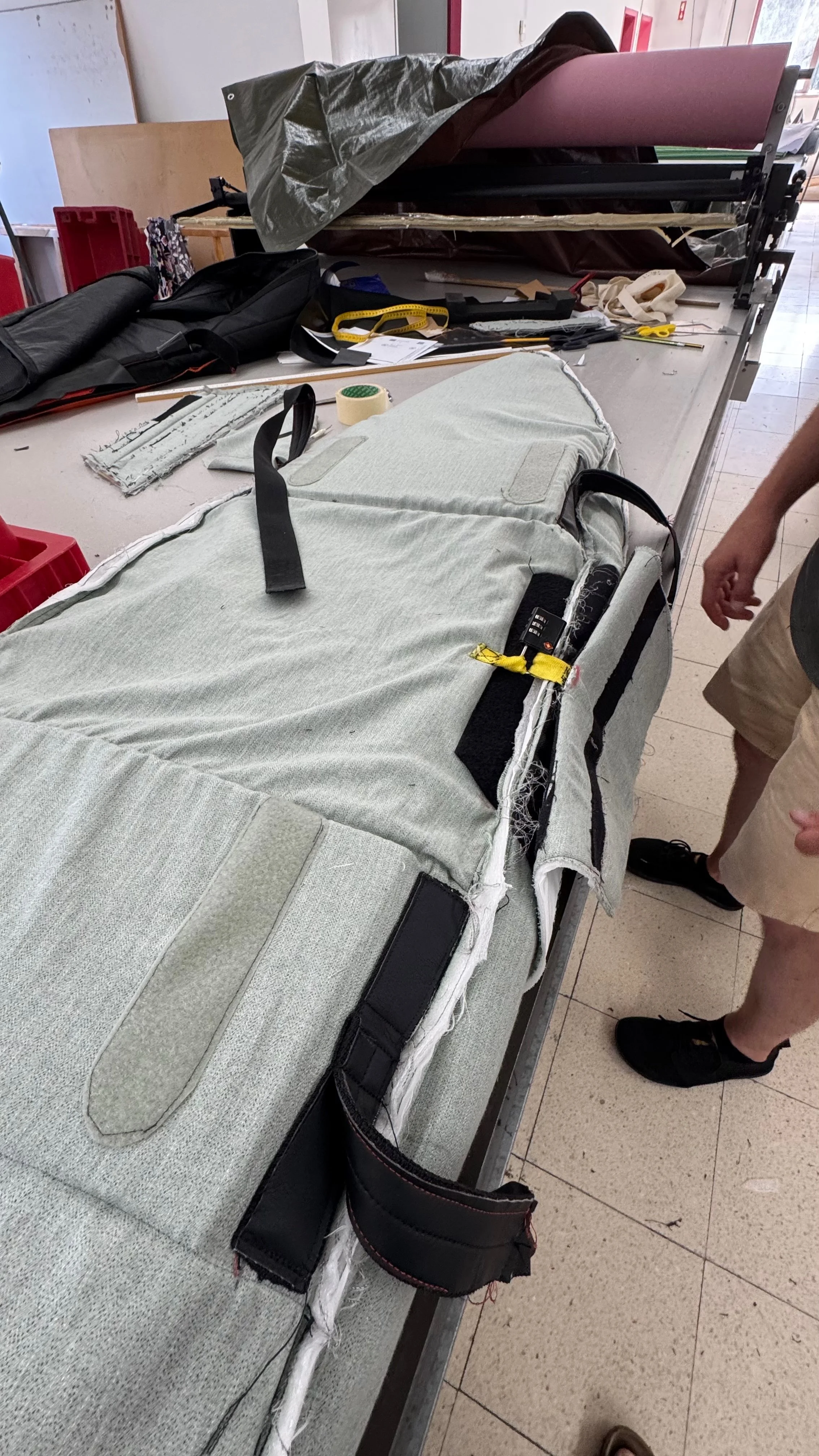

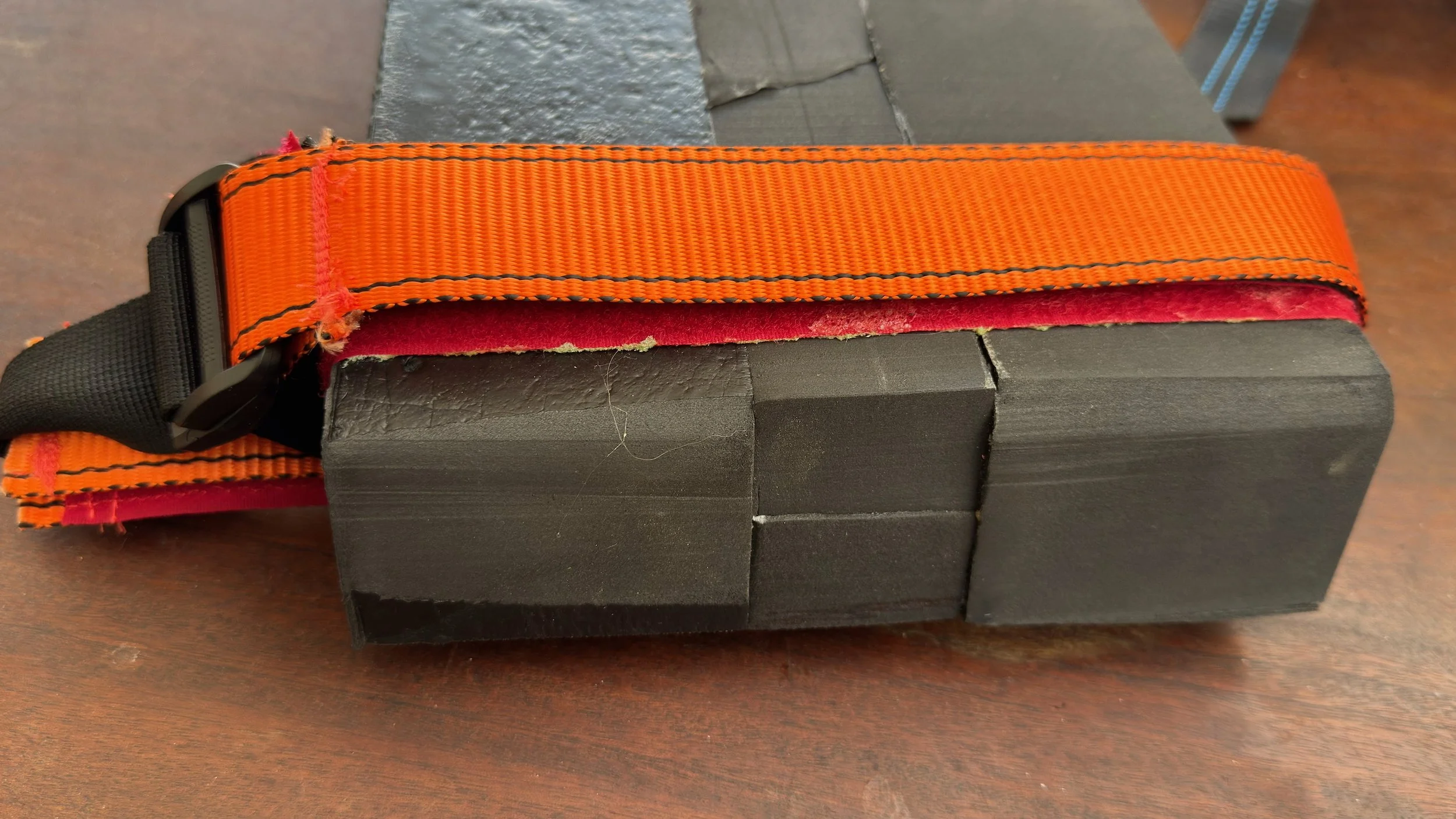

Prototyping (Australia): The core architecture was conceived and prototyped across workshops in Sydney and Wollongong, born from the demands of the daily urban surf commute.

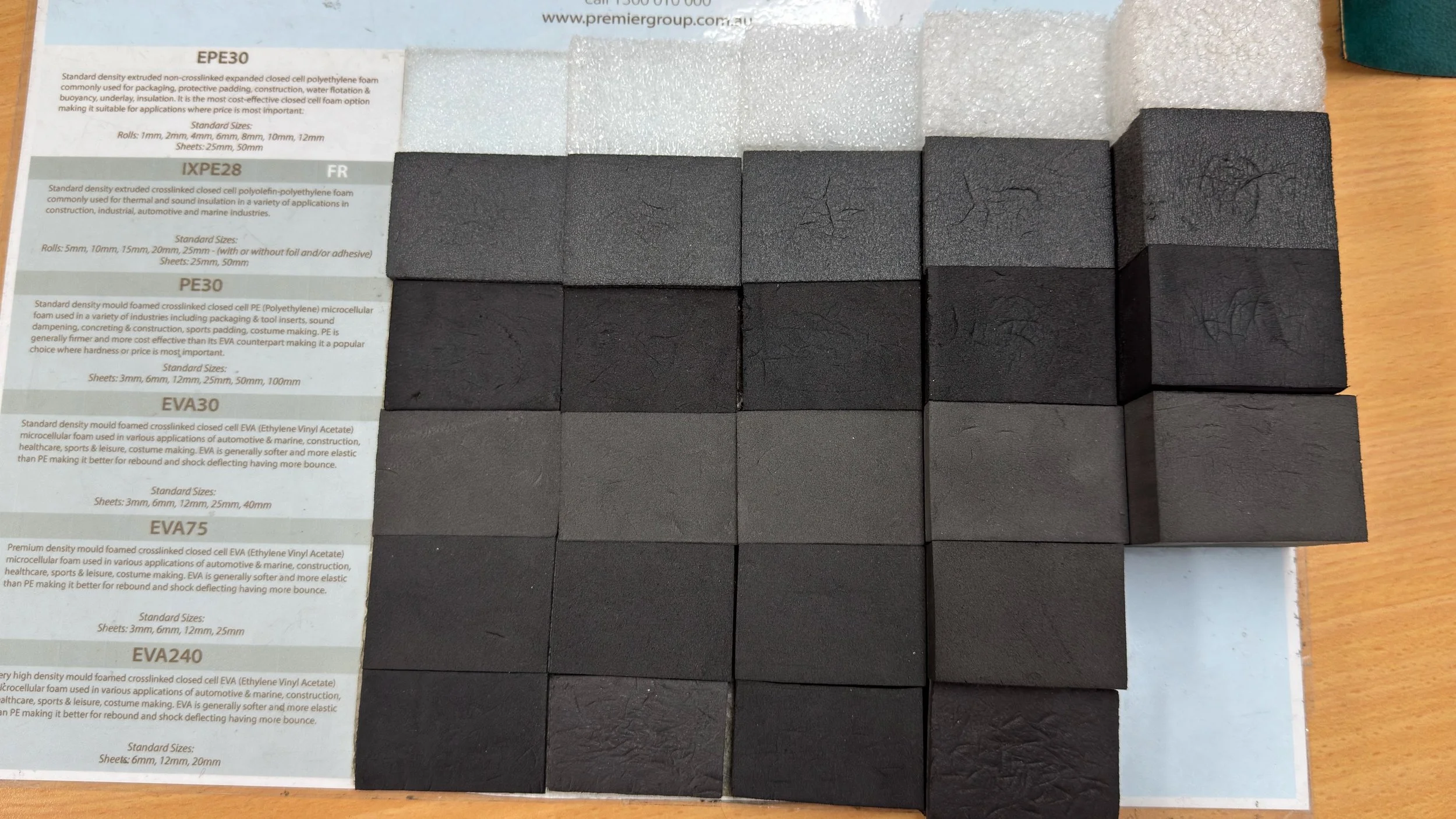

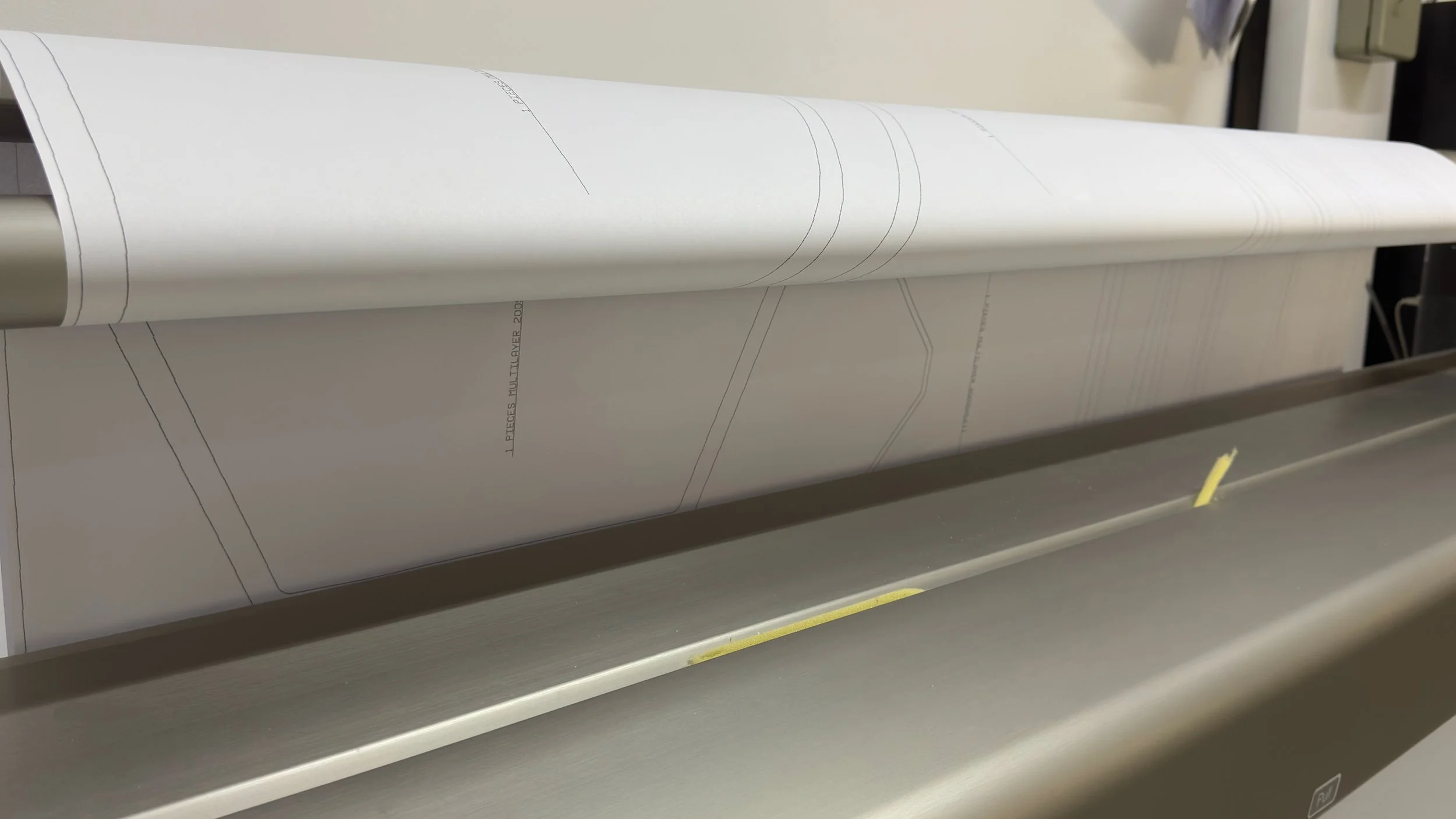

Refinement (Portugal): We moved to the engineered technical textile heart of Europe to collaborate with master makers, pattern makers and artisans. Here, we refined the textile engineering and stress-tested the system against the rugged Atlantic coast, from Daniel’s local Figueira da Foz, to Peniche and Nazaré.

Production (Global): To achieve absolute consistency and scale, we partner with world-class manufacturing facilities in Asia. This ensures every Remora is built with precision repeatability and quality for the global market.

The 50-Year Stagnation

We drive modern cars and ride high-performance boards designed with computational fluid dynamics… but for the last 50 years, connecting the two is stuck in the 1970s.

Loose webbing. Metal cam-buckles that chip paint. The annoyance of highway strap whipping and hum drowning out the surf-tunes. To top it off, the time wrestling with straps in the car park wastes time while the best set of the day rolls through unridden.

We realised that the friction of the surf trip wasn't a necessary evil. It was a design failure, with no innovation since surfing began.

Transit Hardware. Not Luggage.

Protected by a Comprehensive Global IP Portfolio

Not a cover, but Transit Hardware engineered to get your board to the break.

This architecture results from over 10 years of user experience and 3 years of rigorous engineering and testing. While mass-market imitators may attempt to replicate the form, the Remora is the original, and safeguarded by a robust IP portfolio.

We engaged tier-one strategic counsel to rigorously secure the physics, geometry, and utility that define this new category. This includes defensive coverage against inferior variants, ensuring unsafe imitations do not compromise the integrity of this hardware class.

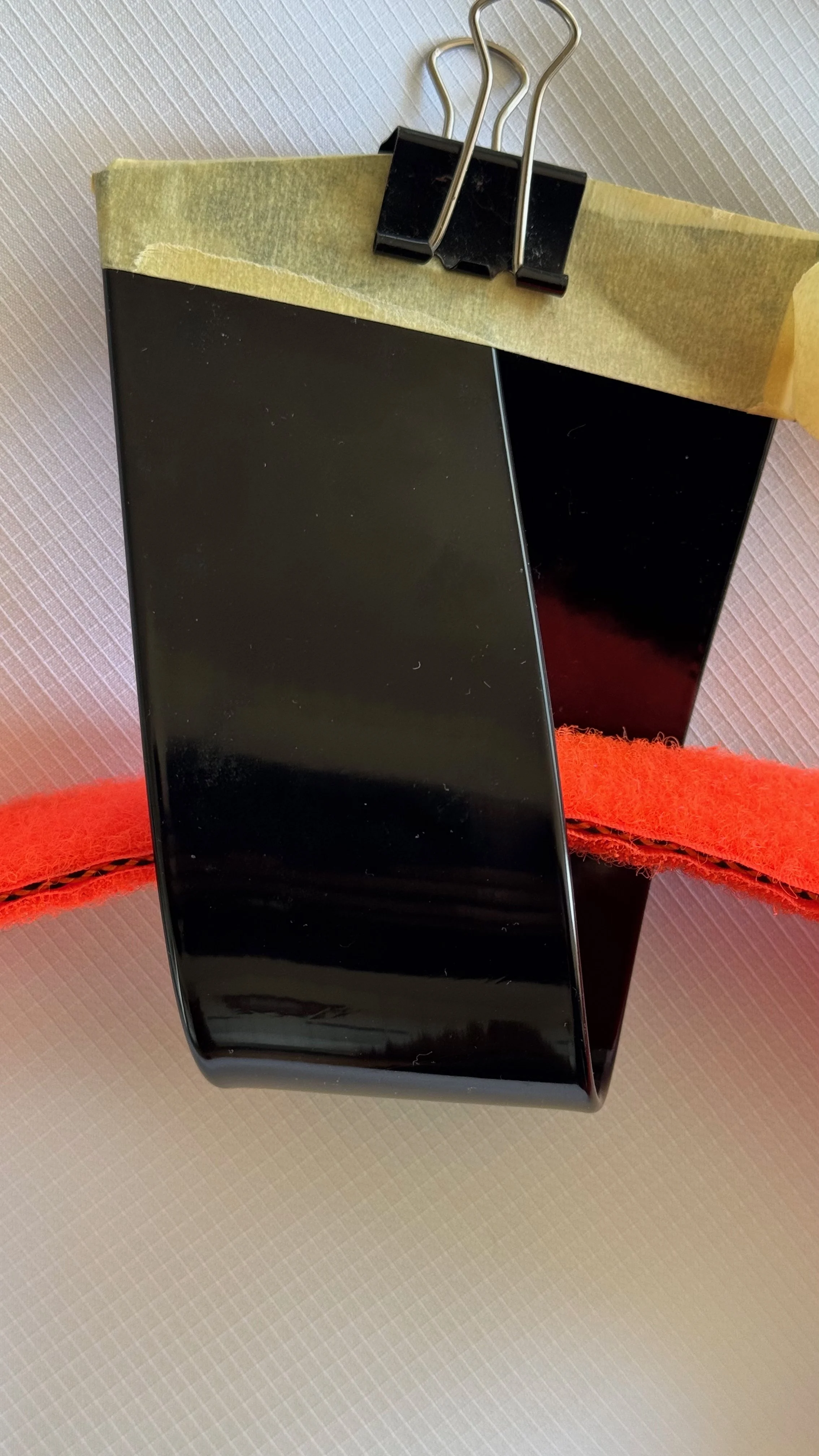

Anti-Crush Geometry: Traditional tie-downs use brute force compression, crushing the board against the rack for grip. The Remora system anchors the bag to the vehicle. Tensile forces are directed strategically through the engineered chassis, isolating the board from crushing forces.

Shear Strength: We replaced metal buckles with High-Cycle Hook & Loop. With engineered orientation, it provides superior holding power without damage. Any surfer who relies on their leash in heavy surf understands the immense strength of this attachment. Over eight generations of patent-pending prototypes, we refined the geometry to force the connections into shear loading, the design angle where the connection is strongest.

Aerodynamics: Loose fabric and webbing ends create drag. Drag creates noise and increases fuel consumption. We designed the variable-length chassis to force the built-in straps into aerodynamically optimized load paths, applying our background in wind-tunnel testing to minimise flutter.

Longevity: Salt corrosion is a failure point for bags with low cost zippers. We use a lockable YKK Marine Grade Zipper on the tail to ensure the system survives the elements, the road, and the risk of opportunistic theft.